Robot-Ready: Preparing Your Infrastructure and Your Team for Automation

TalkTalk Business recently commissioned research into how UK logistics workers – frontline employees and IT leaders – view the future of their industry. This large-scale survey, the details of which can be seen below, revealed some fascinating insights.

Our survey found that both frontline workers and IT leaders believe that automation is set to play an increasingly central role within logistics. In fact, 76% of frontline workers predicted that, within the next 10 years, warehousing tasks will “mostly” or “almost entirely” be performed by logistics robots. Only 24% believed that warehouse workforces would be “mostly humans, assisted by robots”. No respondents believed that warehouse teams would be “almost entirely human”.

Even given its potential for displacing human workers, then, automation is widely accepted as being the future of supply chain management. But introducing robots into your business’s workforce is unlikely to happen overnight – the process demands careful consideration and thoughtful diplomacy.

So what are the key things to bear in mind when you first set out to introduce logistics robots to your infrastructure?

Taking stock

First things first: to figure out where you want logistics automation to take your business, you need to establish where you’re at right now. The first stage of any automation implementation involves analysing your existing processes to identify inefficiencies that automation could help with. The more data you can collect on your processes, the easier it will be to reveal potential optimisations.

It’s worth bearing in mind, however, that automation may not be the answer to every inefficiency. In some cases, processes can be reconfigured without the need to introduce robots. In these early stages, it’s better to take a measured and steady approach to implementing automation, rather than throwing the baby out with the bath water. You can always go back and add automation to areas of your infrastructure at a later date – better to proceed conservatively than expend time and money on unproductive solutions.

One eye on tomorrow

Of course, implementing logistics automation isn’t solely about making things run smoother today – it’s also about future-proofing your business for tomorrow. Investing in logistics robots isn't cheap, so you want to ensure that any new machinery aligns with your plans for two, five, ten years down the line.

For example: how scalable is your planned automation, and how does it fit in with plans for expanding existing warehouses or adding new ones? How will the rollout be aligned to any future milestones? Should your existing growth plans be re-examined in the context of your new automation plans?

Once automation becomes an integral part of your supply chain management, it will need to keep pace with your growth or you risk building gaps into your new and improved processes. At the same time, you don’t want to be sitting on an excessive – and expensive – reserve of robots, many of them surplus to requirements until much further down the line.

As with so much in logistics, timing is everything.

Don’t neglect data

Logistics robots can do more than just assist human workers, or move items from A to B. They can also act as invaluable sources of data, providing big-picture insights into your processes and the opportunities that exist to optimise them.

These optimisations can be identified in two ways: either by data analysis, or by AI. The two are subtly different: data analysis involves looking solely at historical data in order to identify patterns and trends, while an AI cross-references large amounts of data and makes assumptions – shaped by machine learning – in order to make accurate predictions as to how those patterns and trends might evolve over time.

When making your automation plans, it’s important to factor in how you’ll gather, store, analyse and respond to the invaluable data that your logistics robots will provide. A strong network and resilient connectivity will be vital – both for controlling your various points of automation, and for gathering and analysing the information they generate.

Keeping everyone in the loop

Logistics is a team sport, and so every key stakeholder within your business should be kept aware of – and involved in – your automation plans.

Automation projects can be complex and lengthy, and a strong project manager will maintain solid lines of internal communication throughout. (This project manager may need to be brought in externally if the required skill set does not already exist within the business.)

By being open about aims, rationales and timelines, your business can ensure that every employee receives the training they need to make your automation rollout as smooth as possible. Any knowledge gaps – or resistance from blindsided employees – risks delays and additional costs.

Get your network up to speed

While all the above is taking place, it’s vital to undertake an expert survey of your existing IT network. Chances are, it will require an overhaul to ensure it’s fit-for-purpose to control and interconnect your shiny new logistics robots.

Once automation becomes an integral part of your processes, you can’t afford to have lengthy downtime occur due to network outages, weak connectivity or cyber attacks. You need a scalable network that can stay one step ahead of your automation needs – particularly so if you’re planning to have AI-powered forecasting and strategising in the mix.

With TalkTalk Business, your network is designed around you. You’ll have the speed, flexibility and rock-solid resilience you need to fully embrace automation – and the data you need to future-proof your business. Logistics robots stand ready and waiting to help you revolutionise your warehouses – so get ready with TalkTalk Business.

Learn more about how logistics is evolving – and how these changes are viewed by industry insiders. Read our exclusive whitepaper: AI, Automation and Where Logistics Goes Next.

About the research

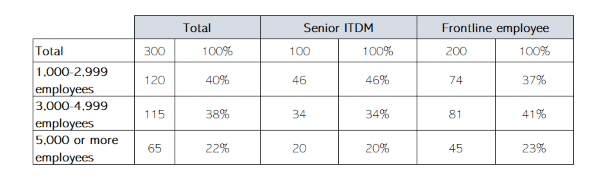

In September 2022, we commissioned a survey by Vanson Bourne of 300 senior IT decision-makers and frontline employees in business sizes ranging from 1,000-2,999 employees to those with 5,000 or more.